Commentary: How resilient is China’s ‘world’s factory’ to supply chain shifts?

NEXUS FOR FOREIGN BUYERS

Yiwu’s robust production performance reflects China’s broader shift from real estate to manufacturing investment. In the first quarter of 2024, China’s industrial production rose by 6.1 per cent and manufacturing investment increased by nearly 10 per cent against a 5.3 per cent GDP growth rate.

While China delivers affordable products globally, overcapacity has increased geopolitical risks and trade tensions, highlighted by Xi Jinping’s recent European trip, aimed at mitigating these tensions. China’s industrial utilisation ratio dipped below 75 per cent in early 2024, the lowest since 2016 – excluding 2020 at the outbreak of COVID-19 – revealing potential resource waste.

Yiwu’s export resilience is fuelled not just by its low-cost products but also by a sophisticated network of information exchanges and collaborative production across enterprise boundaries. Its rapid production and delivery capabilities allow it to handle small orders efficiently. This flexibility starkly contrasts with large manufacturers, which rely on highly organised, large-scale production.

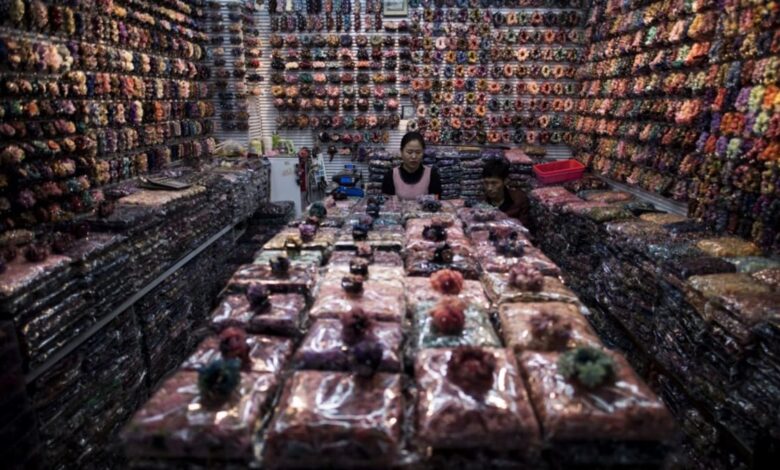

As the nexus for foreign buyers and a wide range of suppliers, mainly small- and medium-sized enterprises, Yiwu demonstrates unique organisational skills that enable quick and cost-effective production tailored to specific orders.

Yiwu’s production and delivery capabilities are anchored in its extensive industrial clusters, which foster both cooperation and competition among closely located enterprises. These clusters are organised around Yiwu’s 78 industrial parks, which are home to over 4,500 small and medium enterprises (SMEs). These SMEs are bolstered by the local government provisions of digital tools, flexible production technologies and support services, complemented by the application of production standards by industrial associations.

Yiwu demonstrates China’s capacity for large-scale collaborative production involving multi-layered supply chains. Though export revenues from products like lighters may seem modest, their production is underpinned by complex supply chains incorporating over 30 components, including materials, precision moulds and electrical automation. With rising labour and material costs, maintaining cost competitiveness requires innovation. This necessitates not only high-precision machine tools but also robust coordination to meet diverse production and safety standards.

Large-scale co-production also has application in other industries. Companies like SHEIN, an emerging fast fashion brand, have revolutionised the sector, outpacing traditional players like Zara.

Unlike Zara, which relies on in-house production, SHEIN depends on thousands of SMEs and organises a flexible “small-batch” production approach that caters to rapid product design, manufacturing and delivery.

By harnessing big data and AI algorithms, SHEIN quickly adapts to market trends. SHEIN introduces between 700 and 1,000 new products daily, and updates around 50,000 new items weekly, compared to Zara – which introduces 25,000 new products annually.